Transformation introduction

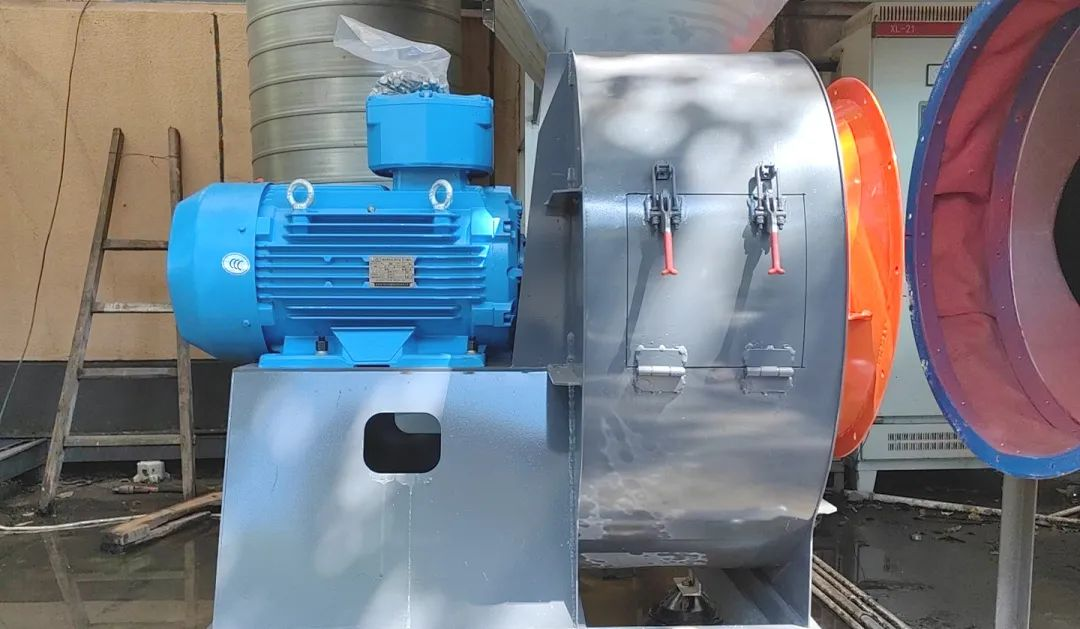

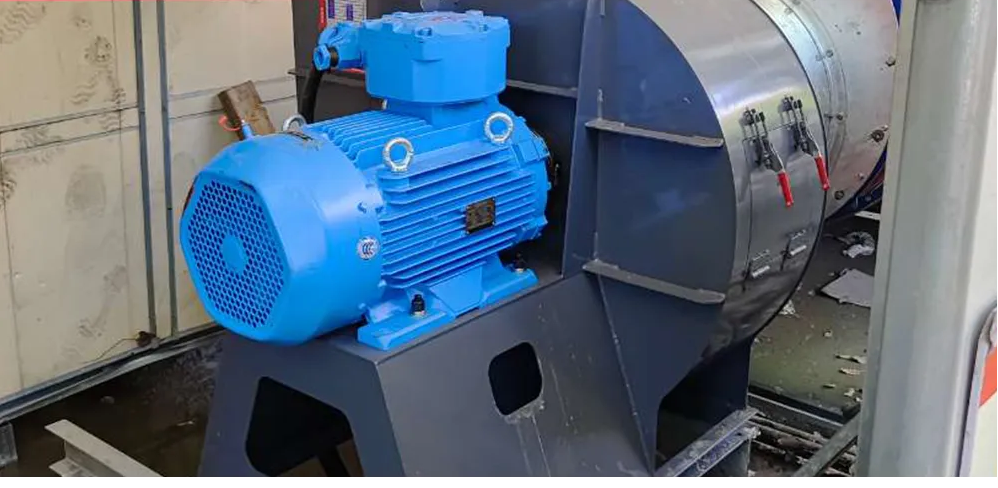

This energy-saving transformation project of YFB3 dust explosion-proof three-phase asynchronous AC motor, aimed at the scene of dust-containing waste gas emission treatment, adopts the overall explosion-proof design of smart fans for replacement and transformation, and is equipped with intelligent control system modules to ensure safer and low-carbon production of enterprises.

In the energy-saving transformation of this scene module, through the energy-saving system of explosion-proof PMSM intermittent motor+ explosion-proof impeller + intelligent control system, a safe and efficient explosion-proof energy-saving transformation solution is created. It is an industry initiative that highly integrates environmental protection, energy saving and safety, helping enterprises to improve new quality productivity.

Energy-saving effect analysis

The transformed smart fan can be switched manually and automatically, has the ability of self-control operation, perfectly adapts to the operating conditions, is in the efficient operation range, greatly reduces energy consumption and waste, and the energy saving rate of the transformation reaches 47%. The fan adopts an overall explosion-proof design to ensure the safety of the overall operation.

Application scenario of explosion-proof fan

The use scenarios of explosion-proof fans are mainly concentrated in environments with flammable and explosive gases, dust or steam to ensure air circulation, reduce explosion risks and ensure the safety of personnel and equipment. The following are some specific usage scenarios of explosion-proof fans:

1. Coal mines and mining industry. Ventilation of underground mines, mine tunnels, and tunnels. Explosion-proof fans are used for ventilation to reduce the risk of gas accumulation and explosion and ensure the safety of the working environment.

2. In the oil and gas industry, explosion-proof fans are used to maintain air circulation and prevent the accumulation of flammable and explosive gases in the process of oil and gas extraction, processing, separation, and storage.

3. Chemical industry. Toxic, flammable and explosive gases or dust may be generated during chemical production and storage. Explosion-proof fans are used for ventilation to ensure the safety of the production environment.

4. In some specific areas (such as solvent recovery and dust treatment areas) of the pharmaceutical and food industries, explosion-proof fans may also be needed to ensure air quality and safety.

5. Special industrial environments such as dust explosion hazardous areas (such as flour mills, wood processing plants), paint spraying rooms, etc. Explosion-proof fans are used to maintain air circulation and prevent the accumulation of dust or flammable gases.