Product Introduction

Value-added transformation service

Wolong Nanyang transformation service, for the entire process line of processing equipment surface rust removal and painting renovation project, that is, the equipment is renewed, the control is renewed, and it is intelligent. At the same time, during the investigation, we will diagnose the operating status of all processing equipment on the process line and provide customers with free rectification and optimization suggestions. This transformation solves many pain points for customers.

For the treatment of corporate waste gas, Wolong nanyang Conservation has completed a series of energy-saving transformation projects for high-efficiency and intelligent environmental protection fans, with a single device saving 232,000 kWh of electricity per year. The entire environmental protection fan is composed of a GE brand high-efficiency PMSM motor and a high-efficiency fan. Relying on a variety of sensors and intelligent frequency converters, the fan can automatically adjust the power according to the algorithm under different working conditions to achieve efficient use of energy. Wolong's high-efficiency and intelligent environmental protection fan eliminates connectors such as drive belts and couplings, and drives the wind wheel through direct drive connection, which greatly increases the fan transmission efficiency while reducing the equipment failure rate, improving the equipment life, and reducing maintenance labor and material costs.

Transformation Service

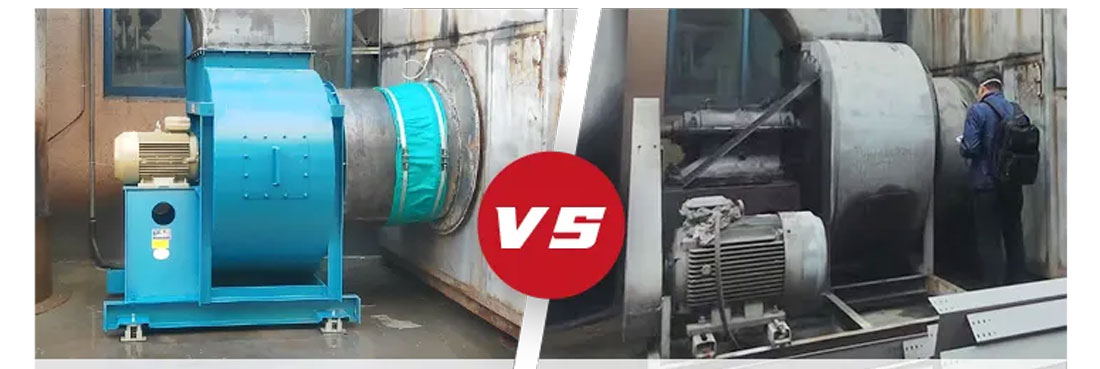

For the waste gas treatment of the company's plate casting process workshop, we have comprehensively renewed and upgraded its workshop environmental protection fans, replacing the original belt-driven traditional fans with Wolong's high-efficiency and intelligent environmental protection fans, and installing smart metering meters (data can be viewed remotely). And reserved IoT ports to prepare for IoT management of equipment throughout the plant.

Energy-saving transformation effect

Through the comparison of data before and after the transformation, the average daily operating power of the equipment dropped from 59.96kW to 30.9kW, with an energy saving rate of 48.47%; the daily power consumption of each device dropped from 1,439kWh to 741.6kWh, saving 697.4kWh per day, and a power saving rate of 48.46%, which is close to half of the original power consumption, and an annual power saving of 232,480 degrees. At the same time, the operating air volume has also been significantly increased after the transformation, meeting the air volume and pressure requirements of the spray tower and the filter tower, and there is more than 20% air volume redundancy, which provides a guarantee for the subsequent increase of production equipment. The equipment occupies less space and has lower operating noise.

It not only meets the company's production and environmental protection requirements, but also achieves a high energy-saving effect, ultimately saving energy and reducing carbon emissions for the company and saving electricity costs.