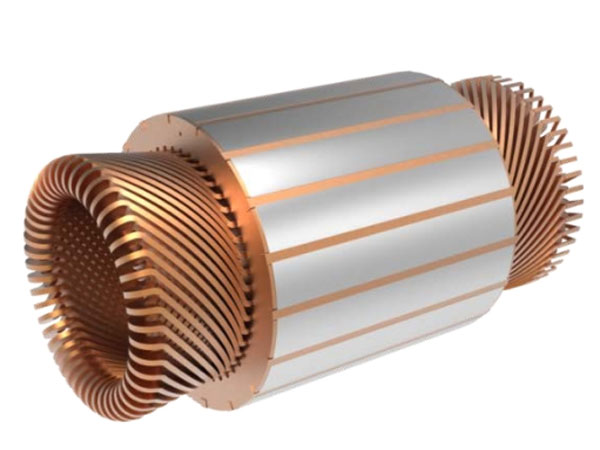

Rotor

The rotor features the squirrel cage design, with cast aluminum rotors being widely utilized. These rotors are produced using either centrifugal aluminum casting or die-casting techniques, where molten pure aluminum is poured into the slots of the rotor core, resulting in a single-piece construction that integrates the rotor bars and end rings. The structural integrity and manufacturing process of cast aluminum rotors guarantee the motor rotor's reliability, and also endow the motor with outstanding torque properties. For larger capacity motors, copper bar rotors are employed, which benefit from dependable bar securing and end ring welding procedures. Additionally, the protective ring design of high-speed motors further ensures the reliable operation of the copper bar rotor.

Stator

The coil is crafted from polyester film and reinforced with glass cloth, utilizing either low-powder mica tape with a high mica content or medium-powdered mica tape with an abundance of mica. Following the VPI (Vacuum Pressure Impregnation) process, a pristine white coil emerges from the production line. After the billet is extracted from the wire, it proceeds through the VPI process to transform into a finished unit. The winding and insulation are meticulously engineered to provide exceptional electrical performance, mechanical strength, resistance to moisture, and thermal stability.

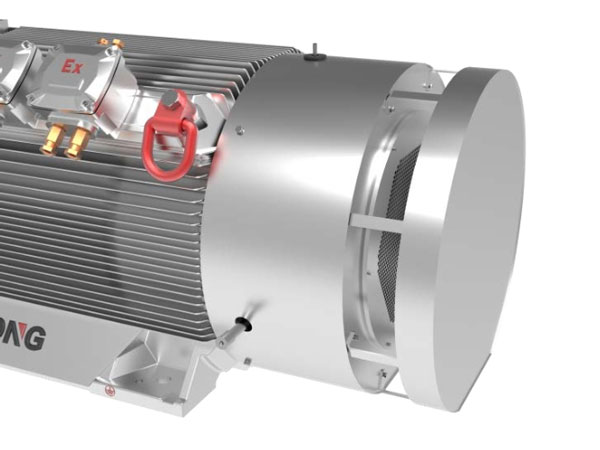

Frame

Motor Frame

The motor frame employs a fully digital platform for structural and fluid multi-physics field simulations. This simulation platform retains the original patent's structure and design, utilizing mature, high-strength cast iron (or steel as an alternative). The frame boasts exceptional structural redundancy, outstanding heat dissipation properties, and ample inherent frequency isolation margins for the entire machine. It is engineered to endure significant mechanical shocks, maintain a superior vibration level, and ensure a lower temperature increase in the motor.

Low Noise Fan Hood System

The low-noise fan cover system comprises a fan cover body, an air guide cylinder, a protective window, and a silencer plate. Its compact structure and lightweight design facilitate vibration reduction. The air inlet is situated on the side, which optimizes the avoidance of obstacles behind the motor, minimizing adverse effects on ventilation and reducing noise caused by energy loss during propagation path changes. The system also incorporates sound-absorbing materials that absorb noise, thereby lowering the overall motor noise. Additionally, the fan cover is rated IP22, ensuring that hands cannot come into contact with the fan.