Different 3 Phase Induction Motor products have different advantages and applicability. Due to different working conditions, the requirements for motor parts are also different. For example, for heavy-duty working conditions, there are special requirements for motor bearings and shafts, and for densely populated places, the vibration and noise requirements of the motor are stricter; When the environmental dust is large, the protection level of the motor must meet the necessary protection requirements.

Under the guidance of the overall policy of energy saving and low carbon, the market prospects of high-efficiency motors are more optimistic, and for permanent magnet motors with relatively high efficiency levels, due to some specific fault factors, there are certain limitations in some specific applications, one of the more typical problems is the rotor magnetic steel loss or falling off.

We have also had a special discussion on the problem of magnetic loss of permanent magnet motor, the main reason is high temperature and large current; The high temperature problem may be combined with the design and application of the motor itself, but a factor that can not be ignored is the motor cleaning problem, when the motor cleaning problem, will be due to the stator and rotor friction serious heating, directly leading to the loss of magnetic steel. When the magnetic steel is lost, the reliability of the connection with the fixed bracket will become worse, and then the magnetic steel falling off will be derived.

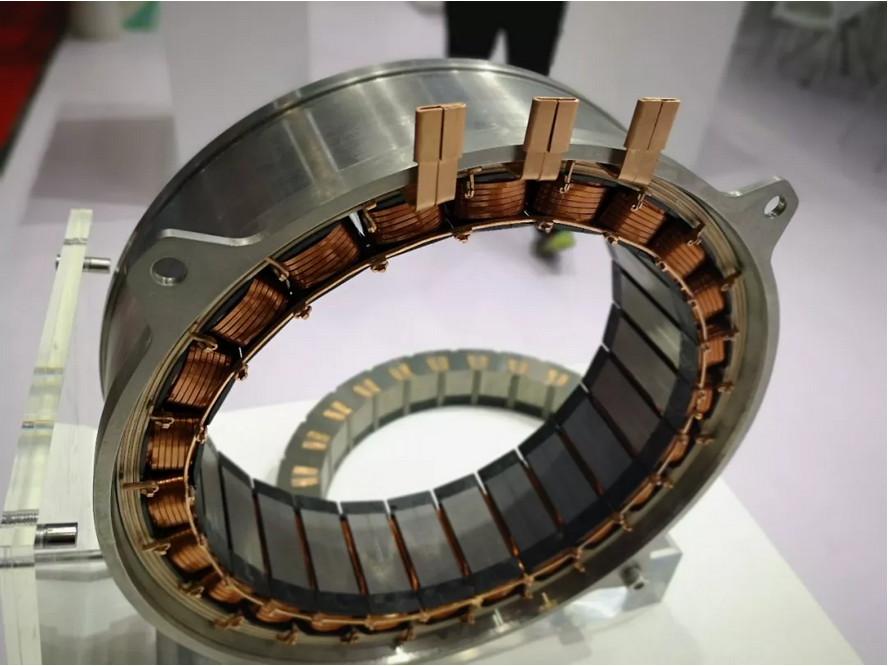

For the falling off of the magnetic steel, in addition to the connection reliability caused by the loss of magnetic, the centrifugal effect of the motor is also a key factor, therefore, the degree of close fit between the magnetic steel and the matrix, the performance conformity of the binder, and the necessary mechanical stability measures are all important contents of the permanent magnet motor magnetic steel fixation.

Some motor manufacturers will use a Mosaic method to fix the magnetic steel on the bracket, and take the necessary bonding and fastening measures; Some manufacturers will also use bonding and ring fixing to fix. Especially for the high speed motor, the fixation technology of magnetic steel is particularly important. If you can solve the problem of permanent magnet motor loss and fixed magnetic steel, the efficiency advantage of permanent magnet motor will be more obvious.

Post time: Sep-11-2024