History

Accumulated with abundant asset and brilliant experiences in manufacturing, WOLONG started to reach for higher attempts. To be the leading manufacturer of AC motors & drives worldwide, WOLONG strove to acquire the oversea groups.

In 2011, WOLONG company has acquired strong technical and technological supports. WOLONG’s holdings group successfully acquired 97.94% of the Austrian ATB Group (ATB motor), one of the three major European motor manufacturers and become the actual controller of the ATB Group, and has became a world -renowned and high -strength global motor manufacturer. ATB motor group included the brand Morley in mining industry and Laurence Scott.

Both are excellent in the motor manufacturing. Morley motor, with its nearly 130-year history, has been closely linked to underground coal mining. Currently, the Morley brand is highly esteemed in the global underground coal market and has become synonymous with quality, power, and reliability. It is a manufacturer that can provide the mine motor with high-specification, high-performance, high-quality electrical equipment for the global market. Laurence Scott, the pioneering company that supplied motors for British nuclear power plants, is currently renowned for manufacturing equipment with low starting currents and also equips British naval vessels with generators. Following its acquisition by WOLONG, the company has been honored with the Queen's Award for three consecutive years.

Furthermore, Brook Crompton Motors joined WOLONG group as well. Brook motor stands as a venerable and profoundly skilled participant within the electric motor sector, boasting over a century of mastery in the technology and design of electric motors. With its extensive background in technological innovation and design, Brook Crompton Motors leads the way in motor technology advancements and pioneers in the creation of energy-efficient motors. Driven by technology and innovation, Brook Crompton Motor has developed a complete range of low voltage, medium voltage and high voltage AC motors, including the premium Brook Crompton “W”, “10” series and motors suitable for operation in hazardous and harsh environments. Brook Crompton also provides user-friendly adjustable speed drive packages to provide users with efficient and reliable drive systems.

Schorch electric motor joined WOLONG in 2011.Since its establishment in 1882, Schorch has set the standard for high-quality motors. The company offers a diverse range of driving systems to customers globally, catering to both domestic and international projects. Schorch collaborates with its strongest partners to provide services across various industries, including oil and gas, chemicals, power generation, water supply and wastewater management, shipbuilding, steel and metal processing, test stations, tunnels, and so forth.

Regarding the vibration motor(MVE) and Ex vibration sensor, OLI Brand owns the largest market around the globe. Dating back to the year of 1999, WOLONG has jointly started the business with OLI vibration motor in China.

In 2015, WOLONG Electric Nanyang explosion -proof group Co., Ltd.(CNE), China's largest explosion -proof motor scientific research and production bases,joined the WOLONG Group and succeeded realize the strategic cooperation.

With various types of explosion -proof motor,low voltage asynchronous motor, Ex-proof high voltage motor, and so forth, Nanyang Explosion Group’s motors are mainly used in oil, coal, chemical, metallurgy, electricity, military, nuclear power and other fields.

In 2018, General Electric (GE) joined the ranks of WOLONG. As the oldest manufacturer of commercial and industrial electrical equipment, GE caters to a multitude of heavy industries, encompassing oil and gas, petroleum and chemicals, power generation, mining and metal processing, paper, water treatment, cement, and materials processing. With the abundant experience in electric motor manufacturing, GE provides huge support with WOLONG.

WOLONG, originating in the city of Shangyu and burgeoning in China, is now rising as a global pioneer in the advanced cultivation and innovation of electric motor manufacturing!

Certification

Nemko/Atex

CSA

CE

CC

SABS

TESTSAFE

Adhere to the comprehensive marketing strategy for the electric motor and the entire industry chain: WOLONG has secured the majority of product certifications, enabling it to penetrate the international market.

-ISO standard

WOLONG becomes the ISO 9001 Ex motor manufacturer. ISO standard has evolved into a critical gateway for businesses to surmount international trade barriers and penetrate the global markets. It has also become a fundamental prerequisite for WOLONG to engage in production, business operations, and trade. Qualified with ISO9001 certification(International Organization for Standardization). WOLONG’s motors and equipment are trustworthy and dependable.

-NEMA standard

To confirm that WOLONG’s electric motors meet NEMA's mechanical performance specifications, we conduct thorough testing, which generally includes the efficiency test, insulation resistance testing, starting current and torque test, durability testing, vibration and noise testing and so forth. For low-voltage motor, WOLONG successfully acquired the UL (Underwriters Laboratories), CSA(Canadian Standards Association) certificates.

-IECEx and ATEX standard

For low&high-voltage motor and explosion-proof motor, WOLONG has acquired the IECEx and ATEX certificates. So it’ll be helpful to export motors to European countries(EU).

-TESTSAFE standard

Testsafe, the largest coal product certification body in the Southern Hemisphere,

the acquisition of Testsafe has completely opened up the channel for Chinese coal mining motors to enter Australia, laid a solid foundation for WOLONG’s coal mining equipment to enter the Australian market or other international markets, and it will further enhance the international influence of WOLONG's integration with the international community.

Picture display

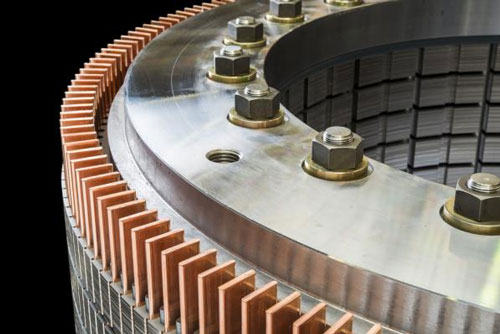

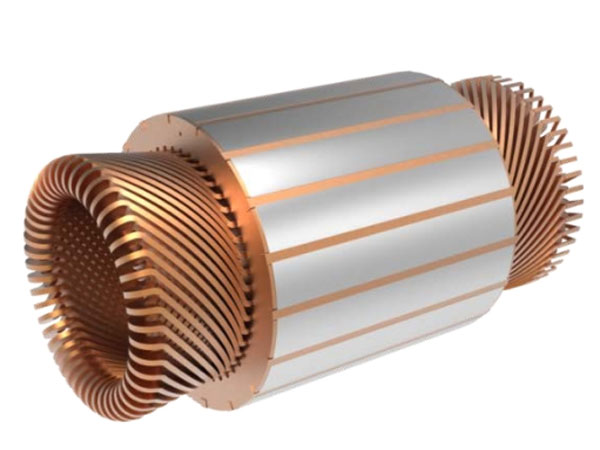

Rotor

The rotor features the squirrel cage design, with cast aluminum rotors being widely utilized. These rotors are produced using either centrifugal aluminum casting or die-casting techniques, where molten pure aluminum is poured into the slots of the rotor core, resulting in a single-piece construction that integrates the rotor bars and end rings. The structural integrity and manufacturing process of cast aluminum rotors guarantee the motor rotor's reliability, and also endow the motor with outstanding torque properties. For larger capacity motors, copper bar rotors are employed, which benefit from dependable bar securing and end ring welding procedures. Additionally, the protective ring design of high-speed motors further ensures the reliable operation of the copper bar rotor.

Stator

The coil is crafted from polyester film and reinforced with glass cloth, utilizing either low-powder mica tape with a high mica content or medium-powdered mica tape with an abundance of mica. Following the VPI (Vacuum Pressure Impregnation) process, a pristine white coil emerges from the production line. After the billet is extracted from the wire, it proceeds through the VPI process to transform into a finished unit. The winding and insulation are meticulously engineered to provide exceptional electrical performance, mechanical strength, resistance to moisture, and thermal stability.

Frame

Motor Frame

The motor frame employs a fully digital platform for structural and fluid multi-physics field simulations. This simulation platform retains the original patent's structure and design, utilizing mature, high-strength cast iron (or steel as an alternative). The frame boasts exceptional structural redundancy, outstanding heat dissipation properties, and ample inherent frequency isolation margins for the entire machine. It is engineered to endure significant mechanical shocks, maintain a superior vibration level, and ensure a lower temperature increase in the motor.

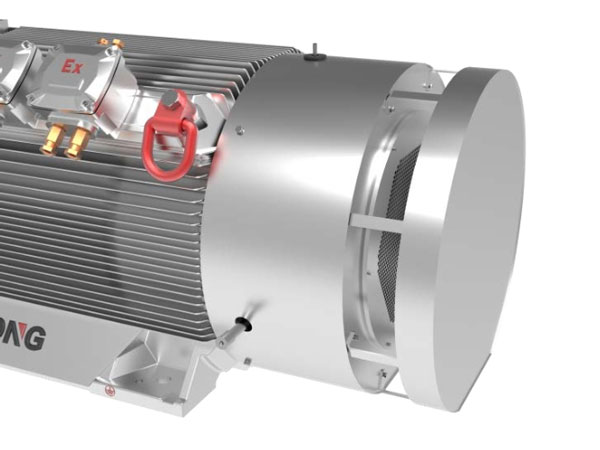

Low Noise Fan Hood System

The low-noise fan cover system comprises a fan cover body, an air guide cylinder, a protective window, and a silencer plate. Its compact structure and lightweight design facilitate vibration reduction. The air inlet is situated on the side, which optimizes the avoidance of obstacles behind the motor, minimizing adverse effects on ventilation and reducing noise caused by energy loss during propagation path changes. The system also incorporates sound-absorbing materials that absorb noise, thereby lowering the overall motor noise. Additionally, the fan cover is rated IP22, ensuring that hands cannot come into contact with the fan.

Applications

As a globally esteemed manufacturer of motors and drive solutions, WOLONG boasts 39 manufacturing facilities and 4 research and development centers (R&D center) across various countries including China, Vietnam, the United Kingdom, Germany, Austria, Italy, Serbia, Mexico, India and so forth.

WOLONG's diverse range of motors finds application across a multitude of industrial sectors, serving equipment such as fans, water pumps, compressors, and engineering machinery. These motors are integral to various industries, including ventilation and refrigeration, construction, oil and gas, petrochemicals, coal chemistry, metallurgy, electric and nuclear power, maritime, and industrial automation, to name a few. WOLONG's mission is to deliver optimal solutions and services to our customers.