YBRB series flameproof three-phase asynchronous motor for pump station

Product Detail

The flameproof three-phase asynchronous motor for YBRB series pumping station (hereinafter referred to as: motor) is a special flameproof motor for driving emulsion pumping station, spray pumping station or other pumping station equipment in the underground mining working face of coal mines.

The motor is manufactured according to the coal industry standard MT/T575 “Flameproof three-phase asynchronous motor for YBRB series pumping station” and the enterprise standard Q/NF252 “Technical conditions for flameproof three-phase asynchronous motor for YBRB series emulsion pump”. It is used to match domestic and imported pumping stations respectively.

The flameproof performance of the motor is made into flameproof type according to the provisions of GB3836.1-2000 “Electrical equipment for explosive gas environment Part 1: General requirements” and GB3836.2-2000 “Electrical equipment for explosive gas environment Part 2: Flameproof type “d”", and its explosion-proof mark is “Ex”. It is suitable for places where explosive gas mixtures of methane or coal dust exist.

Introduction

Y B R B – 160- 4

Y B – Asynchronous motor, flameproof type

S- Conveyor

R- Emulsion

B- For pumping station

250 – Power(kW)

4- Poles

Ex dⅠMb

Ex–Explosion Protection Mark

d–Type of Explosion Protection(Explosion-proof Type)

Ⅰ – Electrical Apparatus Class(ClassⅠ)

Mb — Equipment Protection Degree

Structure Description

1 Cooling method of the motor: The cooling method of the motor is IC411, self-fan cooling.

2 Protection level of the motor: The protection level of the main housing of the motor is IP55, and the terminal box is IP55 (see GB/T4942.1).

3 Transmission method of the motor: The motor has a cylindrical shaft extension at one end, which rotates by means of an elastic coupling or spur gear.

4 The main housing material of the motor is made of steel plate, which has high impact and collision resistance. The other housing parts are made of gray cast iron or steel plate not less than HT250.

5 The motor adopts F or H grade insulation system and undergoes special process treatment, which has good electrical, mechanical, moisture-proof and thermal stability.

6 The motor rotor adopts cast aluminum structure, and the rotor runs smoothly, with low vibration and low noise.

7 The motor adopts rolling bearings specially designed for motors, and the bearings are of well-known brands. The bearing structure is designed with non-stop injection and oil discharge devices.

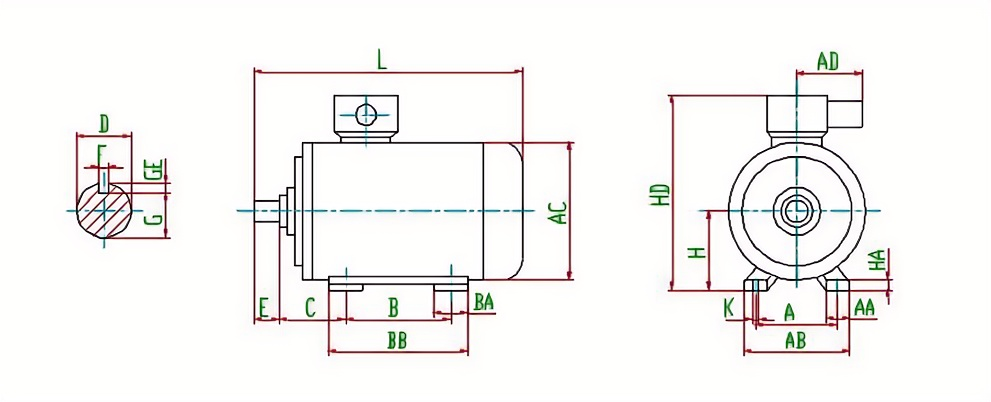

Mounting

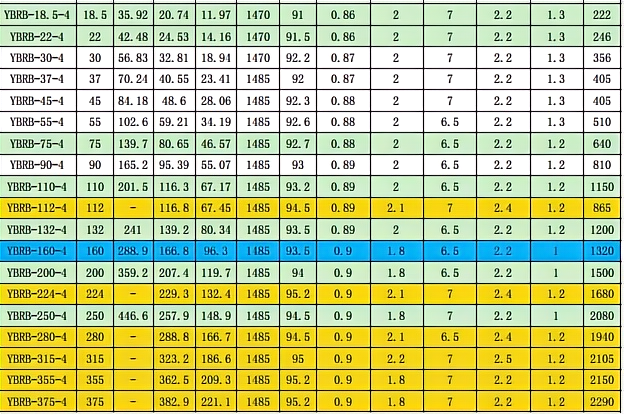

Parameter

Products categories

-

Phone

-

E-mail

-

WhatsApp

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur