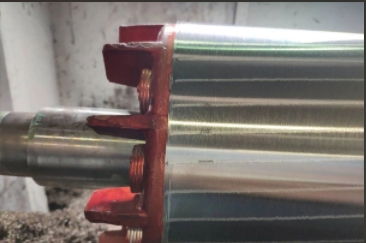

When it comes to the electric motor design, the rotor plays a vital role in determining overall performance. An innovative approach that is becoming increasingly popular is the use of closed slots in cast aluminum rotors. This design choice offers several advantages that significantly increase motor efficiency and functionality.

The main benefit of closed slots is the reduction of the effective air gap between the rotor and the stator. The smaller the air gap, the more concentrated the magnetic field, which is critical for optimal operation of the motor. By shortening this air gap, the closed slot design minimizes the pulsation of the air gap magnetic field. The reduction of pulsation is critical as it weakens the field magnetic potential, which would otherwise lead to poor motor performance.

The equally important thing is that the closed slot configuration helps mitigate losses associated with harmonic magnetic fields. Harmonics create unnecessary vibration and heat, which not only shortens the life of the motor but also reduces its efficiency. By minimizing these harmonic losses, closed slots help the motor run more stably and reliably.

Another significant advantage of using closed slots is improved torque production. This design makes the magnetic force distribution more uniform, thereby enhancing the torque characteristics of the motor. This results in smoother operation and better responsiveness, making closed-slot rotors particularly beneficial for applications requiring precise control and high performance.

As industries continue to seek more efficient and reliable motor solutions, closed slot rotor designs are becoming the best choice. And in our factory, Wolong are always implementing the top-end technique into our products so the use of closed slots in cast aluminum rotors is becoming a strategic choice that can improve motor performance as well. This design not only improves efficiency but also extends the life of the motor. More importantly, it upgrades the motor industry and manufacturers like Wolong. As the biggest manufacturer nationwide even worldwide, Wolong Electric Drive Group is committed to design and produce the top-end 3 phase electric AC motor and other new 3 Phase Induction Motors!

Post time: Oct-22-2024