Under the global “double carbon” goal, important opportunities have been ushered in for the rapid development of high-energy-efficiency permanent magnet motor drive and control systems; Wolong Electric Drive’s large-scale drive business group has concentrated its superior technical resources on the development of permanent magnet drive and control products, and comprehensively launched platform-based , modular high-voltage permanent magnet motor + variable frequency drive system solution, covering ultra-low speed permanent magnet, low-speed permanent magnet, medium-speed permanent magnet, high-speed permanent magnet, etc. The efficiency exceeds Level 1 energy efficiency standards; when driving fans, water pumps and other loads, the comprehensive power saving rate and carbon reduction rate can reach up to 30%. Starting from January 2022, market orders can be fully accepted.

The high-voltage permanent magnet motor developed and launched this time is a series of modular permanent magnet products hatched based on the TEAAC, TETC and TEFC series platforms based on Wolong Group’s global superior technical resources. The development of this product is based on Nanyang explosion-proof technology, integrated with European ATB technology, and combined with Wolong Global Central Research Institute to carry the brand advantages of each region. The permanent magnet drive and control system solution is suitable for multiple scenarios such as green transformation of coal power, high-efficiency smart mines, low-carbon petrochemicals, high-efficiency metallurgy, etc., providing customers with comprehensive, digitally intelligent, green and low-carbon energy power system solutions.

Development Platform

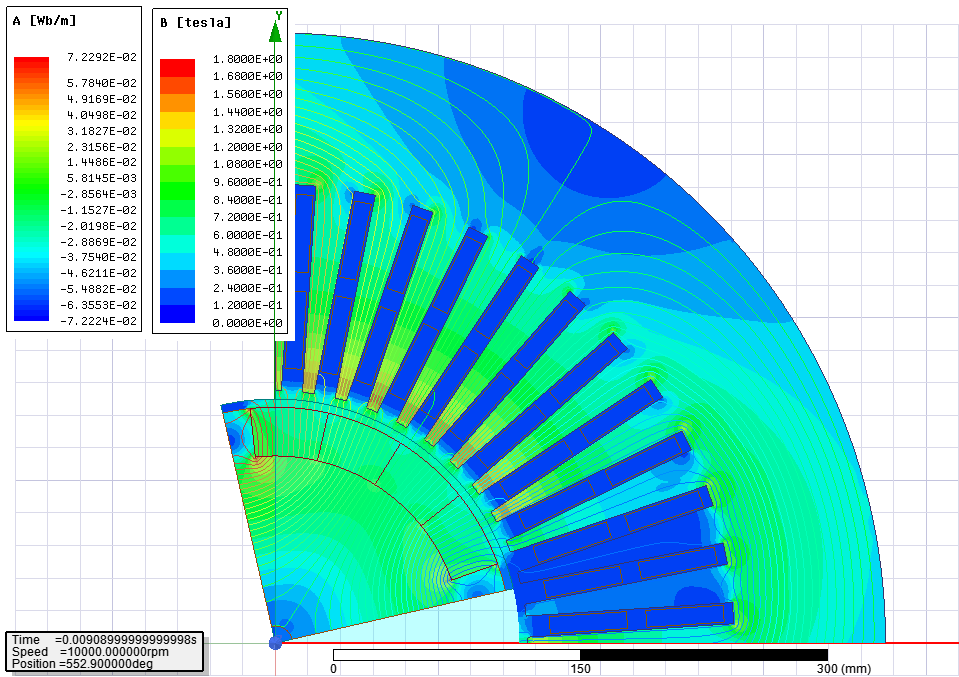

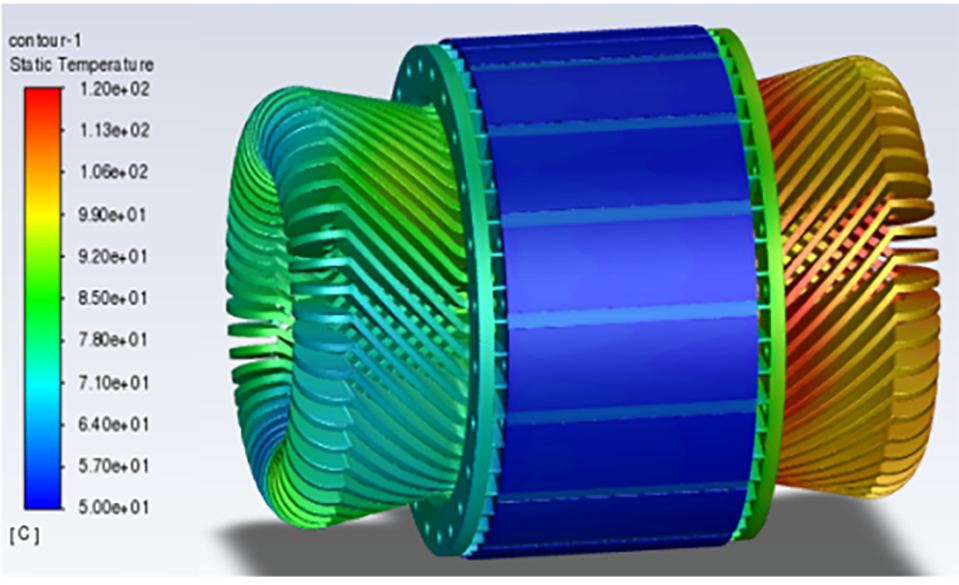

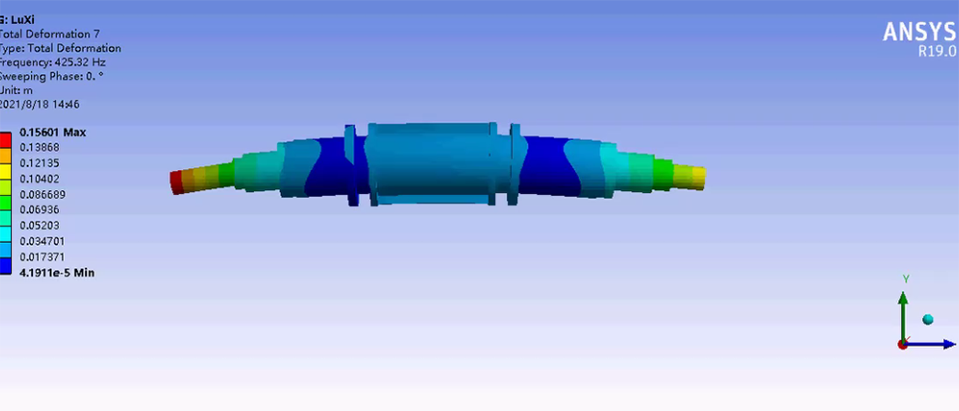

Product development uses advanced digital simulation platforms. Through electromagnetic, fluid, structural and other finite element analysis methods, the field-circuit coupling finite element analysis of the electromagnetic field and temperature field of the multi-degree-of-freedom permanent magnet motor was carried out according to the load and working conditions in different application scenarios, and was carried out Experimental verification of physical motors improves product reliability.

Technical Highlights

Efficiency reaches level 1 energy efficiency

Low vibration, low noise

Use design and technology that maximize the performance of permanent magnet materials to improve the electromagnetic performance of the motor

Platform product, highly versatile and does not require basic modifications

The frequency converter adopts two-level or three-level speed sensorless open-loop vector control.

The inverter has complete protection functions such as undervoltage, overvoltage, overcurrent, overload, overheating, short circuit, IGBT fault, etc.

The frequency converter has good electromagnetic compatibility and meets the network access and system application requirements.

Professional service team

Wolong has a professional service team to provide customers with product life cycle service guarantee, from system design (including unit shaft torsional vibration calculation, power grid parameters, capacity analysis, motor and drive control system solutions) to scientific implementation (including Equipment manufacturing and procurement, installation and on-site commissioning), to considerate delivery (including usage training, after-sales maintenance, transformation and upgrading, etc.), a full set of EPC turnkey services to achieve one-stop service for users.

Post time: Jan-18-2024