In order to improve the quality of the motor, in recent years, the motor noise has been included in one of the quality assessment indicators, especially for the motor operating environment and human contact close to the situation, the noise of the motor has become a very important assessment requirements.

In order to control the asynchronous motor noise, in addition to the design of the stator and rotor slot with the appropriate selection of the stator and rotor slot with the exception of the slant slot can be used in order to reduce the electromagnetic noise of the motor. But exactly how much slot slope is more appropriate, further testing is needed to verify.

In general, the rotor slot slope of asynchronous motors can be taken as one stator tooth pitch, which can also basically meet the requirements. However, in order to further improve the motor noise, it is necessary to explore the optimal slot slope, which requires a large number of calculations and verification.

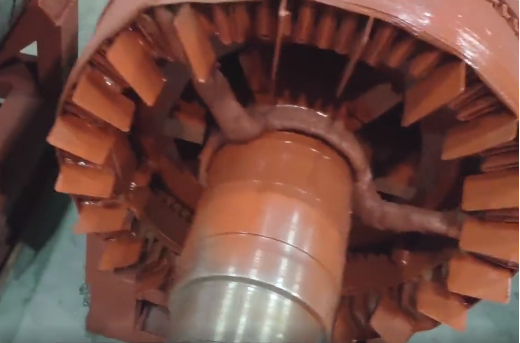

Analyzed from the manufacturing point of view, straight slot motor production and processing to be relatively simple, but when necessary, it will need to be the stator slot or rotor slot torsion. The stator slot torsion is relatively difficult, and therefore, in most cases, the rotor slot tilting. Rotor slot torsion generally through the shaft processing torsion of the keyway to achieve, the more advanced equipment enterprises, the use of spiral punching, in the rotor core manufacturing process to achieve.

Electromagnetic noise causes and avoidance measures

Motor noise has always been a difficult problem to solve, it is mainly produced by electromagnetic, mechanical, ventilation three reasons. Electromagnetic noise in the asynchronous motor is due to the stator and rotor currents in the air gap established in the harmonic magnetic field interaction and electromagnetic force wave caused by the core yoke vibration, forcing the surrounding air vibration and produced. The main cause is due to improper slot fit, stator and rotor eccentricity or too small an air gap.

Electromagnetic noise is caused by magnetic tensions that make changes in time and space and are acted upon by the various parts of the motor. Therefore, for asynchronous motors, the causes of electromagnetic noise formation include:

● Radial force waves in the air gap space magnetic field cause radial deformation and periodic vibration of the stator and rotor.

● Radial force waves of high harmonics in the air gap magnetic field act on the stator and rotor cores, causing them to undergo radial deformation and periodic vibration.

● The deformation of different order harmonics of the stator core has different intrinsic frequencies, and resonance is caused when the frequency of the radial force wave is close to or equal to one of the intrinsic frequencies of the core.

The stator deformation causes the surrounding air to vibrate, and most of the electromagnetic noise is load noise.

When the core is saturated, the third harmonic component is increased, and the electromagnetic noise increases.

The stator and rotor slots are all open, and there are many “slot opening waves” generated under the action of fundamental wave potential in the air gap magnetic field, and the smaller the air gap, the wider the slots, the larger their amplitude.

In order to avoid the problem, the office in the design stage of the product through some effective means of improvement, such as: selecting a reasonable magnetic flux density, selecting the appropriate winding type and the number of associated roads, increase the number of stator punching slots, reduce the harmonic distribution coefficient of the stator windings, appropriate processing of the stator-rotor air gap motor, selecting the stator and rotor groove with the rotor slant groove, the use of the rotor, and other specific measures.

Post time: Jun-14-2024