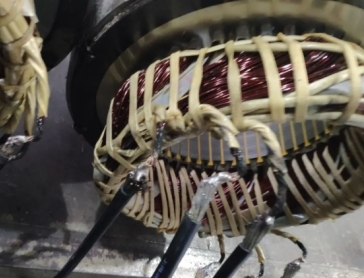

Currently, three phase induction ac motor lead wires represent a crucial element of the electrical configuration of the motor product, encompassing the domains of electrical insulation and conductive issues. Theoretically, provided that the current density selection and installation are in accordance with the relevant norms, the lead wire part will not present any heat-related issues. However, in practice, instances of this type of problem do occur, and in order to gain a deeper understanding of the underlying causes, it is necessary to examine the specific characteristics of the failure in question.

(A). All lead wires exhibit signs of heating-related issues. In addressing this issue, our focus is on the diameter compliance and material composition of the lead wire conductor. In the event of this issue arising, it is likely that it is not simply a matter of individual installation errors, but rather a more systemic problem affecting multiple units. This type of problem can be attributed to the quality of the motor manufacturing process.

(B). Individual lead wire heating problems. This problem is a relatively common fault feature that has been reported during the operation of the induction motor. In the majority of cases, this fault is also accompanied by the problem of terminal board ablation. An analysis of actual fault cases reveals that this problem is caused by a local poor connection of the lead wire. It may occur at the connection position between the motor winding main line and the lead wire, and is more often observed in the fixation of the motor lead wire and the terminal, or the fixation link between the terminal and the terminal board.

(C). The observed heating phenomenon can be attributed to low-voltage operation. This issue bears resemblance to the phenomenon of winding heating. When the motor is operated at low voltage over an extended period of time, the current will increase significantly. Accordingly, the lead wire must also be capable of withstanding a substantial current. In particular, when the diameter of the lead wire is not sufficiently large, the high current density will result in the lead wire becoming heated.

(D) The issue of heating in wound rotor lead wires. This issue is unique to wound rotor motors. The underlying cause of the heating phenomenon may be attributed to various factors, including the welding of the lead wire, the connection of the collector ring, the matching of the collector ring and the carbon brush, and the material of the carbon brush itself. Furthermore, it is a more complex issue. For this type of motor, the ventilation and heat dissipation of the collector ring are of great importance. The temperature of the three ring surfaces of a three-phase motor collector ring varies significantly, which also affects the temperature of the rotor lead. However, the degree of influence varies from one motor to another.

(E) The material and cleaning of the terminal must also be considered. In addition to their role in securing the lead wires and the terminal board, motor lead terminals must also exhibit good electrical conductivity. If the terminal material is of poor quality, in addition to the potential for breakage during the installation process, a more significant issue is that the contact resistance of the connection part will increase, leading to elevated temperatures in the lead wire. Furthermore, residual paint at the terminal, which may result from the lead wire being dipped in paint along with the winding, can also cause local resistance to be too large, thereby leading to a heating problem in the lead wire.

(F). The structure of the terminal block is unreasonable. If the structure of the terminal block is deemed to be unreasonable, it is probable that the connection parts will loosen during the operation of the motor, which may result in the lead wires and windings overheating.

In light of the aforementioned analysis, it is imperative to ensure the operational reliability of the motor products by implementing a robust selection, fixation, and subsequent maintenance process for the lead wires. This approach is essential to prevent the potential damage of the entire motor due to local failures.

Post time: Oct-30-2024