Different environmental conditions for the three phase motor protection level requirements are different, suitable for the operation of the motor in water or other liquids, the motor must have effective protective measures for winding, bearings and other parts, general environment operation of the motor, when stored or operated in a humid environment, is likely to cause serious corrosion to the winding and bearing system, resulting in electrical or mechanical failure of the motor.

When the 3 phase motor is flooded for objective reasons, the winding must be dried before the motor is run, and the insulation of the winding must not be damaged during the disposal process. For the bearing part of the motor, it should be re-filled with grease that meets the requirements after the cleaning and drying of the specification. Like the motor water problems caused by flooding disasters, especially the relatively low protection level of the motor, the motor shell inside will be in addition to water sand and other substances pollution, such motors should be professional motor manufacturing and repair units to ensure the quality of motor operation.

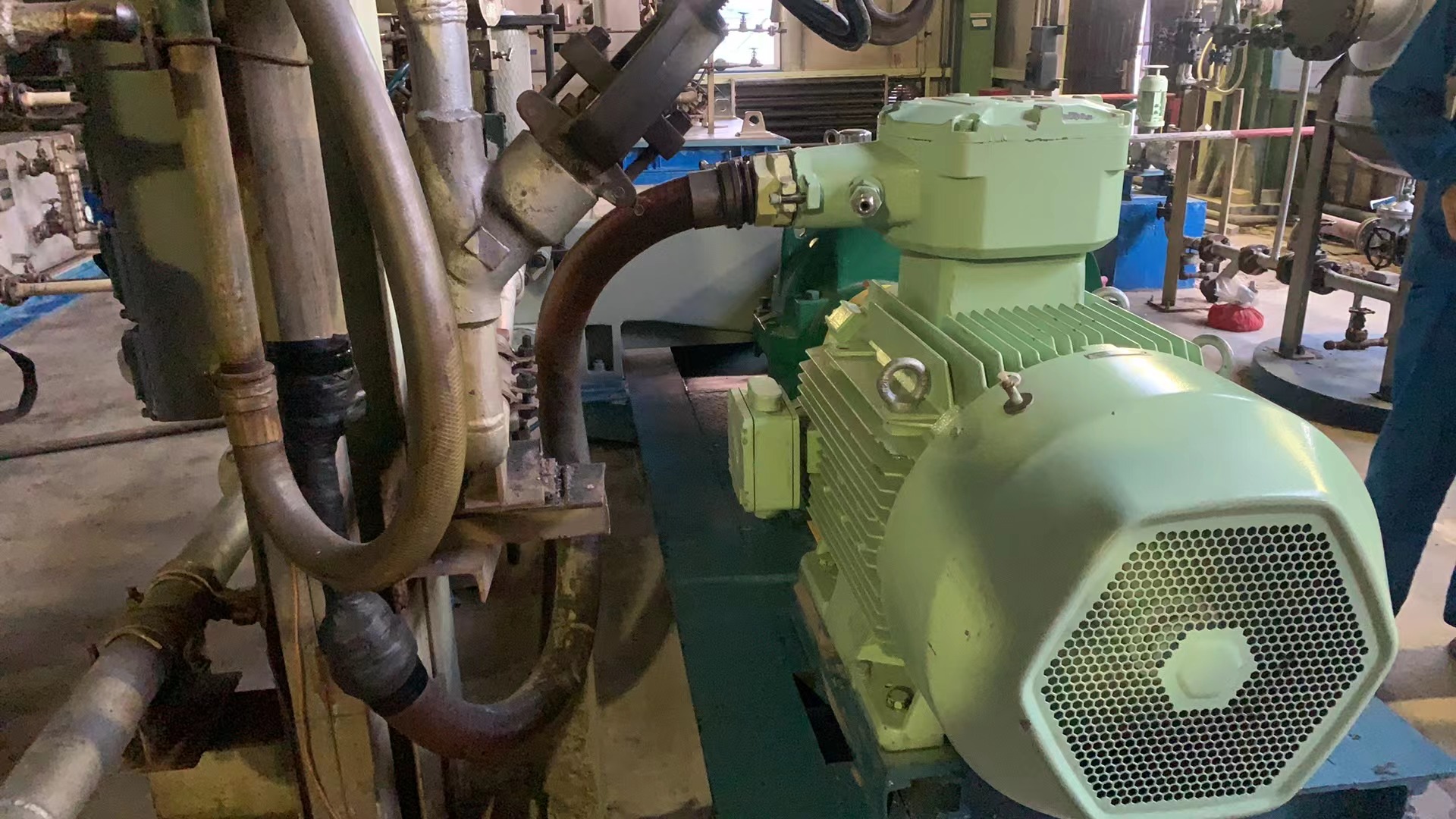

In addition to the above mentioned irresistible reasons, the motor intermittent work, long-term storage and other factors, may lead to the motor cavity moisture and condensation problems, in order to ensure the safety of later operation, before the motor operation, should be carried out moisture treatment, to this end, high voltage motor and other large motors, in the manufacturing is equipped with moisture-proof heating device, when not disassembled motor, the motor can be disposed.

In order to prevent the 3 phase induction motor windings from getting damp, the storage and use environment of the motor should match its protection level.

Post time: Sep-23-2024