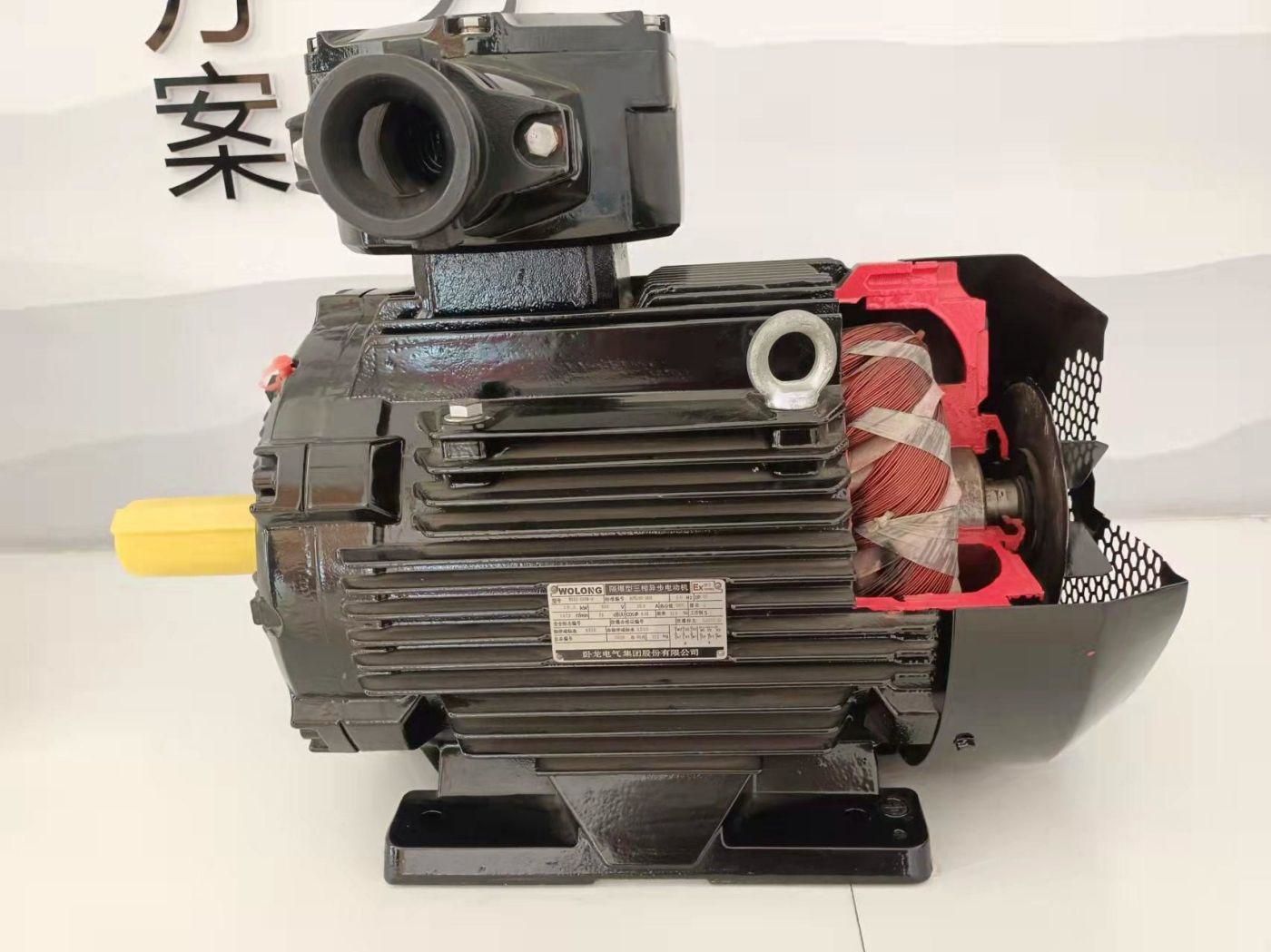

If you work in an industry with hazardous environments, it is critical to understand the precautions and safety measures required when operating explosion proof motors. Explosion proof motors are designed to minimize the risk of ignition of any flammable gases or vapors present in the surrounding environment. The following are a few points to pay attention to when operating explosion-proof motors.

First, it is important to understand the classification of hazardous areas. Hazardous areas are divided into different zones according to the possibility of the presence of explosive substances. These zones include Zone 0, Zone 1, and Zone 2, with Zone 0 being the most dangerous. Explosion-proof motors must be selected according to the specific area in which they operate, because each area has different requirements for motor ratings and enclosures.

Second, proper installation is critical. Explosion proof motors require specific wiring practices and should be installed by a qualified professional. The motor should be mounted securely, remembering that the motor housing and cable glands are designed to prevent any sparks or flames from escaping into the hazardous area.

Regular maintenance is also necessary to ensure the continued safe operation of the motor. The motor should be inspected for signs of damage, corrosion or overheating. Any faulty or worn parts should be replaced immediately. It's also important to clean the motor regularly to remove any dust or debris that may have accumulated, as these can start a fire.

All safety guidelines and procedures must be followed when operating explosion-proof motors. This includes ensuring that all non-Ex equipment is kept out of the hazardous area. In addition, regular inspections are recommended to verify that the motor and its surroundings comply with safety regulations.

Finally, knowing how to respond is critical when an emergency occurs. Become familiar with emergency shutdown procedures, including how to isolate motor power in the event of abnormal operating conditions or potential explosion hazards. Regular training sessions should be held to educate employees on how to effectively handle emergencies.

In conclusion, operating an explosion proof motor requires knowledge and following safety protocols. Knowing the classification of hazardous areas, proper installation, regular maintenance, following safety guidelines, and being prepared for emergencies are all important aspects to be aware of when operating explosion proof motors. By implementing these precautions and measures, you can help protect your workers and maintain a safe operating environment.

Post time: Jun-29-2023