Motor products involve relatively more performance, such as power, efficiency, power factor, vibration, noise and temperature rise, in order to ensure that the performance of the motor meets the requirements, often take some corresponding measures, but in order to ensure certain performance levels at the same time, it may affect other performance. For the vibration and noise problems of the motor, especially for the control of electromagnetic noise, the stator or rotor of the motor will be used when necessary.

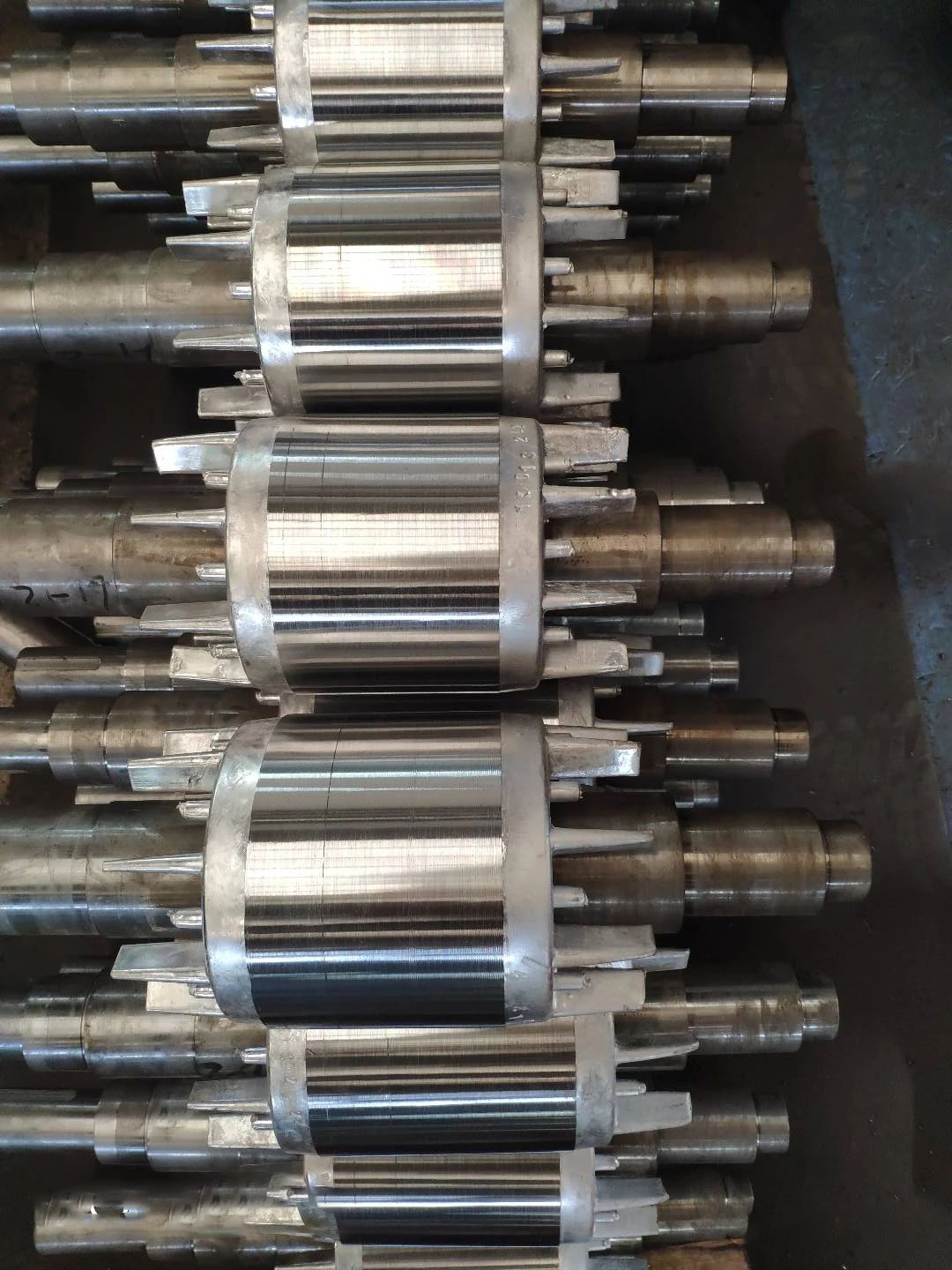

After 3 phase electric ac motor rotor adopts the inclined slot, the electromagnetic torque and induced electromotive force formed are approximately the average value of the same rotor guide bar evenly distributed in a circle, which can effectively weaken the harmonic electromotive force generated by the tooth harmonic magnetic field, thus weakening the additional torque caused by these harmonic magnetic fields, and effectively reduce the electromagnetic vibration and noise of the motor. After the rotor is used, although it will also reduce the fundamental electromotive force induced by the rotor, the general selection of the slotted degree is much smaller than the polar distance, and thus has little impact on the basic performance of the motor, so the rotor slotted is generally used in small and medium-sized cast aluminum rotor asynchronous motors.

Oblique groove is an effective measure to eliminate tooth harmonics. If the noise is electromagnetic noise, the effect is very significant, if it is caused by other reasons, the effect is very small. The chute is too large may also cause the reactance current to increase too much, so that the motor temperature rise has increased, but the general chute situation can not exceed two stator tooth spacing (according to the maximum error estimate of 1 to 1.2 times the stator tooth spacing chute), usually does not have much impact on the temperature rise. If the chute is too small, it can not reduce the noise effect, and even the noise is larger, but it has almost no effect on the temperature rise.

From the perspective of motor processing technology analysis, for the cage motor rotor, the processing technology and related processing parameters do not have much impact, but for the wound rotor motor, the use of the groove will increase the difficulty of wire embedding to varying degrees, so the wound rotor should not use the groove as far as possible.

Post time: Sep-10-2024