For most small specification products, due to the ball bearings with the inner ring and the outer ring relatively fixed at both ends, even if the 3 phase electric ac motor‘s rotor has a certain movement relative to the stator after the motor is energized, it will also leave no obvious marks on the bearing due to the relative fixed characteristics of the bearing itself.

For cylindrical roller bearings with inner ring and outer ring separation, as well as motors with plain bearing structure, traces of axial movement can be seen during motor operation or disassembly.

For large 3-Phase Induction Motor with sliding bearing, the position of magnetic center line of motor can be determined by the relative position difference of rotor axis before and after the motor is energized, and information support can be provided for the later installation of motor and equipment.

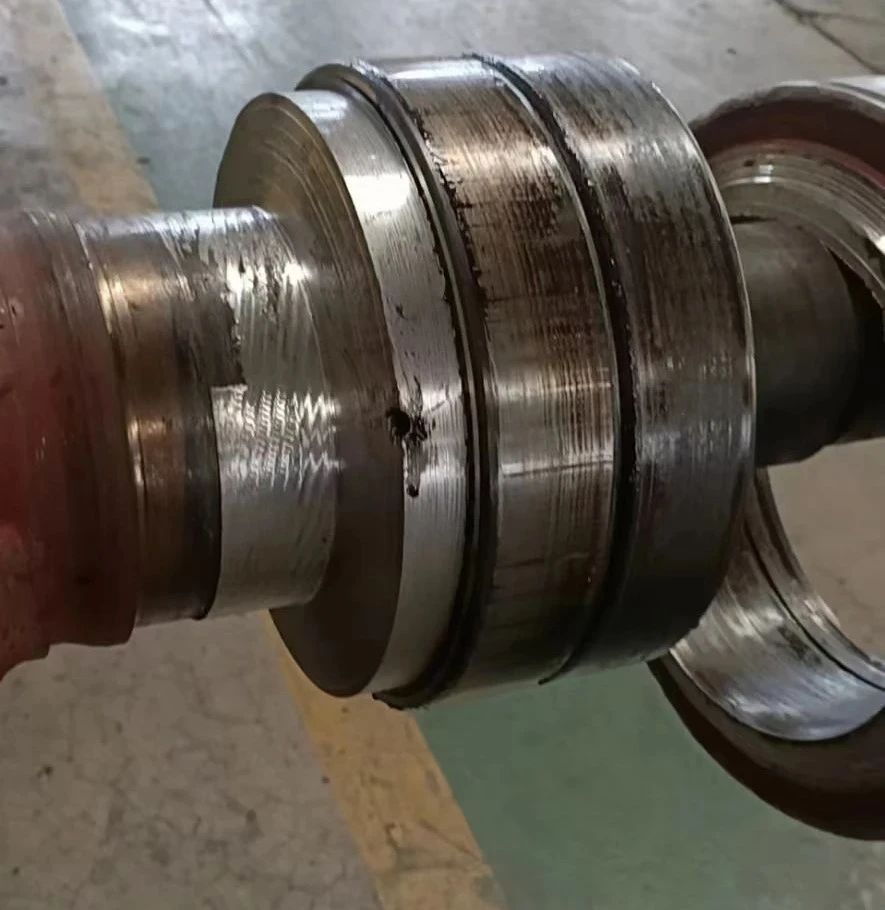

For cylindrical roller bearings with inner and outer rings that can be separated, due to the axial movement of the rotor, it will lead to the axial alignment of the inner and outer rings. Relative to the bearing ball, the difficulty point of the ball is not in the axial center of the ring, which naturally leads to the irrational matching of the inner and outer rings of the bearing body.

From the bearing contact wear marks, when the axial dislocation of the inner and outer rings of the bearing occurs, the contact marks naturally deviate from the axial center line of the ring, and there may be bearing noise, even increased bearing vibration, bearing heating and other serious problems during motor operation.

The direct cause of this kind of problem is that the motor stator and rotor mechanical center line and magnetic center line are not aligned, which is reflected in the design and manufacturing level of the motor. From the actual analysis of production and manufacturing, it is difficult to fully align the stator and rotor with the design, but how to maximize the guarantee or control to a certain level is a direct reflection of the process and manufacturing level of a motor manufacturer. The same design does not necessarily have the same level of products, compared with other products, motor products are easier to be copied, a high level of plagiarism will produce a higher level of motor, on the contrary, simple imitation or plagiarism, it can only look the same but a thousand miles apart.

Post time: Sep-09-2024