Due to the existence of loss during the use of the motor, the temperature continues to rise, if it is not well cooled, it will affect the service life of the motor. The power of the high-voltage motor is generally large, and the value of its loss power is also large, and cooling is especially important for normal use.

For open-type motors, ambient air is generally used to enter the motor directly for cooling, and cold air takes the motor heat directly away and out to the surrounding environment. There are three main routes for air to travel inside the high-voltage motor. One is axial, where cold air enters from one end of the motor and exits from the other end. As long as one end is installed with a fan, it can install a larger diameter fan, cooling is better, and the core structure is compact. The disadvantage is that the ventilation loss is large, the temperature distribution along the motor axis is not uniform, and it is generally used for small capacity motors.

The other is radial, where cold air enters from both ends and exits from the radial vent of the iron core. The disadvantage is that because both ends should be installed fans, the outside diameter of the fan can only be less than the diameter of the rotor. The capacity of the fan is limited, and radial ventilation slots are required to make the motor slightly larger. The advantage is that due to the use of axial fans, the ventilation efficiency is higher, the heat dissipation area is larger, and the temperature along the axial direction of the high voltage motor is more uniform. The other is axial and radial composite ventilation, which is designed by combining the advantages of axial and radial ventilation. It has better ventilation and cooling, and the temperature is more uniform, but the structure is more complex.

Because the insulating material used by the motor has a temperature limitation, the task of motor cooling is to dissipate the heat generated by the internal loss of the motor, so that the temperature rise of various parts of the motor is maintained within the range specified in the standard, and strive to homogenize the internal temperature.

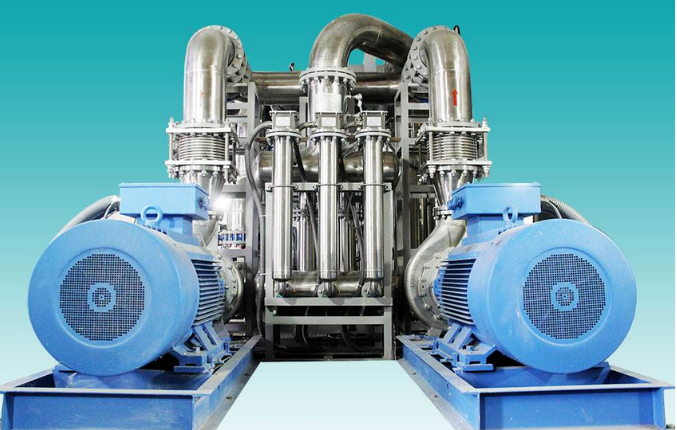

Motors usually use gas or liquid as a cooling medium, common air and water, the corresponding we call air cooling or water cooling. The common air cooling is completely enclosed air cooling and open air cooling; Water cooling is common with water jacket cooling and heat exchanger cooling.

Common cooling method

1, IC01 natural cooling (surface cooling)

2, IC411 self-cooling (self-cooling)

3, IC416 forced fan cooling (strong cooling or independent fan cooling)

4.Water cooling 5.Hydrogen cooling 6.Oil cooling

Post time: May-31-2024