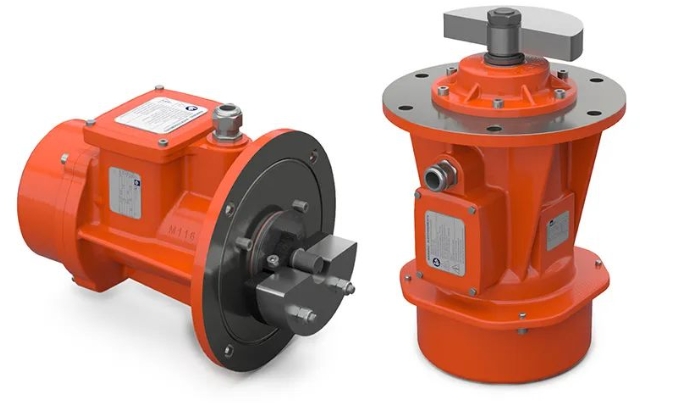

Vertical vibration motor products are widely used in vibration finishing machines, vibration crushers, rotary vibration cleaning machines, vibration dryers, vibration mixers and other equipment, especially in large quantities in rotary vibration screens (circular vibration screens) to improve screening efficiency and screening accuracy, efficiently complete the surface quality of special-shaped parts, and improve the crushing or mixing effect.

01 Inspection

To ensure the normal operation and efficiency of the vertical vibration motor, the motor, cable and connection device should be inspected at least once a quarter. The inspection method is as follows:

1. The power supply of the vertical vibration motor should be cut off and locked, and a warning sign should be given.

2. Check whether the end cover has cracks and whether the end cover screws are tightened.

3. Check whether the cable is damaged, including cuts and wear. If damaged, it should be replaced in time.

4. Check the grounding condition. Make sure that the grounding resistance of the vertical vibration motor housing does not exceed 0.1 ohms. Make sure that the tightening torque of the screws on the grounding terminal meets the specified requirements. Make sure that the tightening torque of all connecting nuts on the terminal board meets the specified requirements, but do not tighten them too much.

02 Maintenance

Vertical motors are used for a long time, so maintenance is essential.

1. The vertical vibration motors SZIE30F~75F produced by OLI-Wolong all use special bearings of vibration sources of internationally renowned brands, which have been injected with special lubricating grease and work normally without maintenance. Do not attempt to repair the vertical vibration motor or replace the bearings without authorization. If you repair or replace it without authorization during the warranty period, the warranty conditions will be invalid.

2. As long as the user does not damage the sealing device when wiring or adjusting the eccentric block, no impurities will enter the housing of the MVE series vertical vibration motor. The dust on the surface of the vertical vibration motor should be cleaned in time to facilitate the heat dissipation of the surface of the vertical vibration motor.

3. In the first month after the user installs and runs the vertical vibration motor, the user should tighten the foot mounting screws with a lever arm extension wrench at least twice, and check it at least once every month thereafter.

4. The housing color of the OLI-Wolong vertical vibration motor is the international universal safety warning color. It is recommended that users do not cover it with other colors. If the customer needs, it can be modified separately.

Post time: Oct-21-2024