Explosion-proof motor for a long time there will be some problems caused by the explosion-proof motor seat failure is mainly manifested in its deformation, explosion-proof motor seat deformation will directly affect the operation of explosion-proof motor.

Explosion-proof motor seat deformation produced by the design, manufacture of two factors:

1, explosion-proof motor design issues: explosion-proof motor design is not fully in accordance with the theory of structural mechanics design of force parts, such as explosion-proof motor seat axial, radial bar size, shape, location of the design; explosion-proof motor seat overall design is not proportional. For example, explosion-proof motor seat processing after the lower part of the remaining effective part is too small.

2, explosion-proof motor production problems: explosion-proof motor production aging is not in place; metal processing fashion card parts and uneven force, processing is complete, after loosening the clamping parts, explosion-proof motor seat deformation due to rebound.

Due to the existence of resonance phenomenon in the operation of explosion-proof motors, often appear at a certain speed, in the start-up process is fleeting. Therefore, the explosion-proof motor seat deformation is not easy to be detected. Deformation due to aging is not in place, it is not easy to be detected. So in the explosion-proof motor production process must pay extra attention.

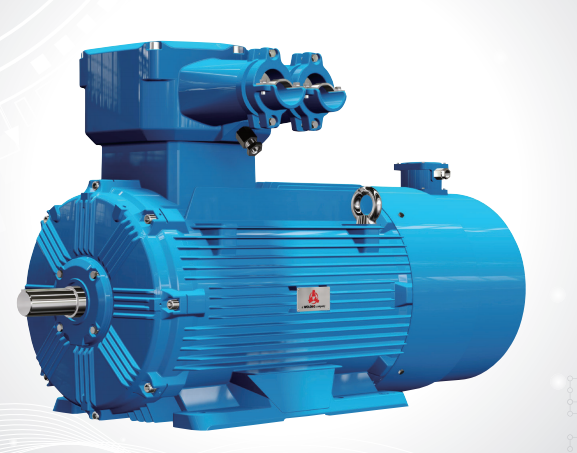

In the motor, the seat is an important component of hardware, AC asynchronous explosion-proof motor seat mainly as a stator core and winding mechanical support, and used to fix the end cover or end cover, in some cases, but also constitute the ventilation system of the wind or wind chamber, and even support the cooler, filter and muffler.

The main loads on the seat during the operation of the motor

(1) gravity load, generally for the stator weight. In the motor with end cover bearing, it also needs to bear the weight of rotor, and in the suspended hydro generator, it needs to bear the weight of the rotating part of the unit, the upper frame and so on.

(2) Radial force caused by unilateral magnetic pull and thermal expansion of the core.

(3) In the case of internal press-fit and rounding punch, some parts of the frame have to withstand the axial rebound force of the core; in the case of a suspended hydro generator, the axial water thrust force.

(4) torque. Including the transient electromagnetic torque when the load changes suddenly and the generator is suddenly short-circuited.

General motor seat in the processing, transportation, installation, but also will be subject to clamping force, cutting force, lifting force, etc.; requirements for sealed motors (such as hydrogen-cooled turbine generator or explosion-proof motors), the seat will also have to withstand the role of the test pressure, in the use of the end cover bearings and belts (or gears and other transmission agencies) transmission, the seat and its feet will also be subject to belt tension (or gears and other transmission agencies) The role of the belt tension (or gears and other transmission mechanism). Therefore, in the design of the seat, the general mechanical calculation of the seat often includes its stiffness, strength and intrinsic vibration frequency calculation, half of the seat needs to be the strength of the seam plate bolts calculation, welded seat needs to be the foot plate weld stress calculation, which is mainly the seat of the stiffness calculation.

Technical requirements for seat processing

The parts to be processed by the machine base mainly include the two end stops, end face, inner circle, foot plane, foot hole, fixed end cover, outlet box and lifting bolts. For the separation type machine base, it is also necessary to process the assembling surface, assembling screw holes and pin holes. The technical requirements that should be met when machining the machine base can basically be summarized as follows.

The dimensional accuracy and roughness of each machining part should be in accordance with the drawings. Among them, the precision and roughness requirements of the two end stops and the inner circle are higher, and the center height dimensional accuracy should also be accurate.

The form and position tolerance of each machining surface should be in accordance with the drawing. Among them, the coaxiality of the two end stops and the inner circle, and the end face runout of the two end faces are the key to the machining of the seat. Special emphasis: if the shape and position tolerance is not specified, the maximum and minimum values should be within the size tolerance; the foot plane should be parallel to the axis.

The distance of the foot hole to the centerline of the seat should be symmetrical and conform to the specified tolerance.

The thickness of each part of the yoke should be uniform after the magnetic guide seat is processed. The indexing of the magnetic pole holes should be equal and their positions shall conform to the drawing.

The assembling surface of the detachable seat should be stable and reliable in positioning, and the original requirements should be met when it is reassembled after dismantling.

Post time: Jun-25-2024