At the beginning of the 21st century, ATB has developed into the third largest fan motor brand in Europe, with production bases all over the world. It has three domestic production bases in Shaoxing, Zhejiang, Wuhan, Hubei, and Nanyang, Henan. In 2011, ATB Group was acquired as a whole by Wolong Group. It cooperates with technical teams such as Wolong Nichidonic Drive and Control Research Institute, Wolong Nichidonic Fluid Machinery Research Institute, and Japan Research Institute, and cooperates with well-known domestic and foreign universities such as Politecnico di Turin in Italy. Developed the world’s leading clean room EC fan product series.

product description

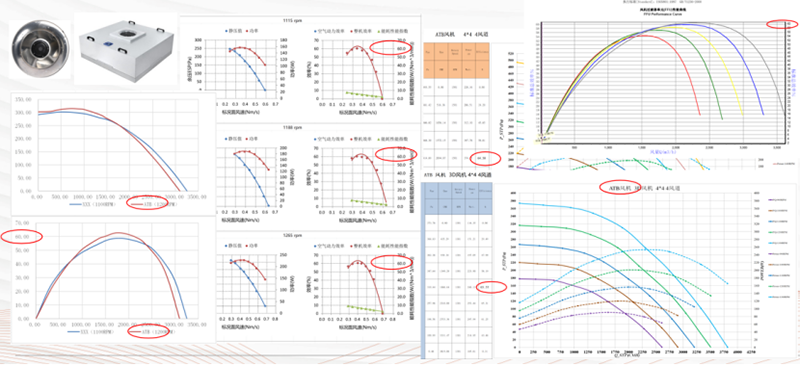

ATB has launched a high-efficiency permanent magnet EC fan specifically for FFU in the clean room industry. It has the characteristics of high efficiency, high reliability, and high intelligence. It supports 0~10V speed regulation and Modbus communication. It has passed UL, CE, CCC and other relevant certifications and can be used for 2 ×4, 3×4, 4×4 and other box sizes.

The main technical parameters

Input voltage: 1~200-277V; 50/60Hz

Control signal: RS485/0-10V

Maximum input power: 450W

Working environment temperature: -25~45℃

Main impeller specifications: 310, 355, 400, 450

Protection level: IP44

System efficiency: ErP2015

Certification: UL, CE, CCC

Design Features

Impeller: A self-built high-performance simulation workstation conducts fluid, strength, and noise simulation bionic design to achieve ultra-high fan efficiency, high reliability, low noise, low vibration, and low cost.

Motor: Permanent magnet motor magnetic circuit simulation technology achieves high power density, low cogging torque & torque ripple; adopts unique insulation and high thermal conductivity plastic sealing structure to reduce temperature rise, improve insulation reliability and IP protection capabilities; prevent bearing electric shock Corrosion design; achieve ultra-high motor efficiency and high reliability.

Control: The single-phase power supply adopts active PFC design to achieve high power factor; it supports wide voltage input, reduces harmonic components on the input side, and reduces pollution to the power grid. The advanced DFC software control algorithm collects motor operating parameters in real time, analyzes them, provides timely feedback on the motor operating status, and provides point-to-point maintenance information. It can realize functions such as interconnection, group control, and remote monitoring.

System: Optimized combination of high-performance aerodynamic impeller (air duct), high-efficiency permanent magnet external rotor motor, and energy-saving controller, with compact structure, low energy consumption, low noise, low grid pollution, and high reliability, providing customers with full satisfaction It is a system solution for optimal air performance of the entire machine.

Post time: Jan-05-2024